- EN

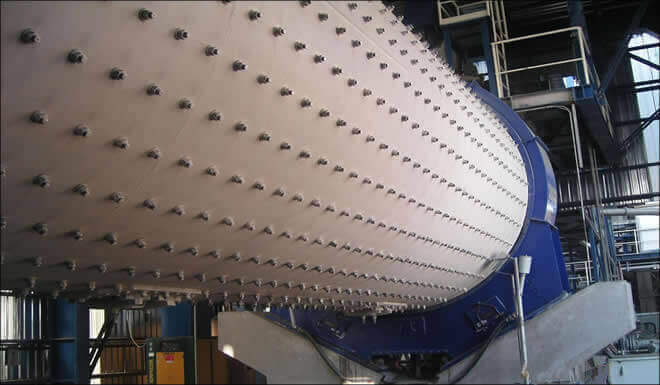

Ball Mills serve as indispensable equipment in multiple industries, offering efficient grinding and material processing capabilities. In the cement industry, Ball Mills are pivotal for grinding raw materials and clinker into fine powders, contributing to the production of high-quality cement.

In Cement Industry Ball Mills play a crucial role in reducing raw materials and clinker to achieve the desired fineness required for cement manufacturing, ensuring optimal quality and performance.

Also, for other industries, Ball Mills find extensive use in diverse sectors such as mining, chemicals, ceramics, and more. They are versatile tools for grinding various materials into fine powders, facilitating numerous industrial processes.

In addition to above, Vertical Roller Mills (VRMs) stand as robust alternatives in the cement industry, offering enhanced grinding efficiency and energy savings compared to traditional Ball Mills. VRMs efficiently grind raw materials and cement clinker, utilizing rollers and a table for grinding, leading to higher grinding efficiency and reduced energy consumption.

As a trusted supplier, we offer a range of Ball Mills and Vertical Roller Mills tailored to meet the demands of the cement industry and various industrial applications. Our mills are engineered for efficiency, reliability, and optimal performance, ensuring seamless operations in material grinding and processing.

Partner with us to access cutting-edge mill solutions designed to optimize production processes, whether in cement manufacturing or across diverse industries such as mining, ceramics, chemicals, and more.

Please contact us or explore our comprehensive range of Ball Mills and Vertical Roller Mills available for various industrial applications, designed to deliver superior performance and efficiency.

For more information, you can visit our partner webpage by clicking following link and contact us for your inquiries to make sure you can have the best competitive proposal:

SUADİYE MAH. BAĞDAT CAD. A NO: 399 B KADIKÖY/

İSTANBUL/ TURKEY

Postal code: 34740

Accreditations & Awards

Privacy Policy

Terms & Conditions

LEAVE YOUR EMAIL

Get Free Support

Leave Your Email and get detailed information about our products.